FIBRE:

A Fibre is a material which is several hundred times as long as its thick.That are very small in diameter in relation to their length.

TEXTILE FIBRE:

THE raw materials which is used to produce yarn in order to make fabric is called textile fibre.in other words . filament or fine strand of sufficient length,flexibility, and strength to be spun into yarns and woven into cloth is called textile fibre.

classification of textile :

1.classification according to their nature>>>>>>>>a)NATURAL FIBRE b) MANE MADE FIBRE

2

.CLASSIFICATION OF botanical>>>a)vegetable fiber eg:cotton,jute

classification zoological>>>>>>b)animal fibre eg:wool,silk

classification of chemical>>>>c)mane made fibre eg:polyester,polyethylene etc

3)classification according to their thermo plasticity >>>>>a)thermo plastic eg:polyester

b)Non-thermo plastic eg:cotton

4) classification according to length >>> a)staple b)filament

TEXTILE FIBRE PROPERTIES:

A)PHYSICAL PROPERTIES

B)MECHANICAL PROPERTIES

C)CHEMICAL PROPERTIES

A) PHYSICAL PROPERTIES

1.TENACITY

2.FIBRE MATURITY

3.ELONGATION

4.BURNING BEHAVE

5.PILLING &SWELLING

6.DURABILITY &EXTENSION

B)MECHANICAL PROPERTIES

1.STRENGTH

2.RIGIDITY

3.ELASTICITY

C) SOLUBILITY IN aqueous & organic salt.

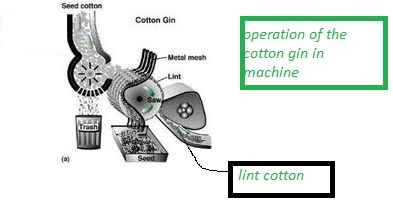

here difference type of fibre image that you can find visually

*cotton

jute

bamboo

banana