- TYPES OF COTTON:

- American upland cotton fibres:>>fairly white,strong and dull,staple length range (22-32)mm

- American Pi ma Cotton>>>fine,strong,lustrous,silky,creamy brown white in colour.length(35-38)mm

- Egyptian cotton fibres>>>>light brown,fine strong,length(32-38)mm

American cotton grading:

- middling fair

- strict good middling

- good middling

- low middling

- strict good ordinary

- good ordinary

INDIAN COTTON GRADING:

- Super choice

- choice

- super fine '

- fine

- fully good

- good

- fully good fair

EGYPTIAN GRADING

- EXtra fine

- fine

- good

- fully good fair

- good fair

- fair

structure view of cotton :

the cotton fibre is a single plant cell.it cross section oval,compared with the normal hexagonal plant cell.all plant cell cotton has the following:

chemical composition of cotton

step 1.

The first step in the ginning operation is when the cotton is vacuumed into tubes that carry it to a dryer to reduce moisture and improve the fiber quality. Then it runs through cleaning equipment to remove leaf trash, sticks and other foreign matter. Ginning is accomplished by one of two methods.

flow chart of cotton spinning

- CARDED YARN: A yarn produced from fibres that have been carded but not combed .carding is process ,which eliminates fibres too short for inclusion in the spun yarn. the process also removes dirt and foreign matter still remaining in the fibre mass and arranges the fibres into a very dense layer

- combed yarn : in this process the fibres arc arranged ina highly parallel form and additional short fibres are removed ,producing high quality yarns with excellent strength;fineness,and uniformity.

- process flow chart for 40"s combed and card yarn :

carded yarn manufacturing process

cotton purifying stages:

- Step One: Mechanical Purification and Cake Formation. The first step in our process is to open the dense tufts of fiber from the bales

- Step Two: Scouring. Next, a solution containing sodium hydroxide is pumped into the kier

- Step Three: Purifying

- Step Four: Fiber Finishing

- Step Five: Opening and Drying

- Step Six: Carding.⇒⇒

subjected to a series o

carding: This is necessary for all staple length fibres otherwise it would be impossible to produce fine yarns.the fibre must be straight and removed impurities the work is done on a carding machine

CARDING PROCESS:

|

| 3.2 CARDING PROCESS |

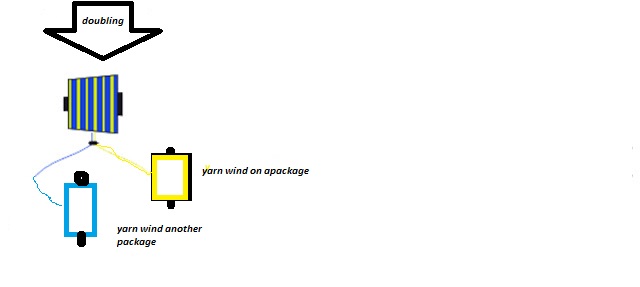

DOUBLING:The process of combining two or more slivers ,rovings,or yarns into one .after carding,severals slivers are combined

|

| 3.3 doubling |

ROVING:

No comments:

Post a Comment